Intelligent Pigging & In Line Inspection

Intelligent Pigs or Smart Pigs are used to inspect and collect a variety of data about the condition of a pipeline, this is called an In-Line Inspection or ILI.

Examples of the data collected during an ILI are:

- Temperature

- Pressure Differential over a pig

- Pig Speed

- Pig Location and location of intrusions and debris

- Inertia of pig

- Location and depth of damage, wall thickness variation etc

- Debris location

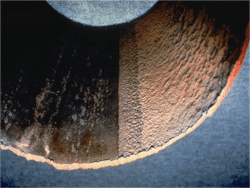

A clean pipeline surface is needed in order to run an intelligent pig, and imperative to the integrity of the data collected.

Pipeline After Pre ILI Chemical Cleaning

Preparing A Pipeline for Intelligent Pigging – Pre Clean

Making assumptions that the pipeline is clean, using the wrong type of pig, or not performing enough pre-cleaning pig runs, can be detrimental to the pigging program and lead to costly problems when running smart pigs, or needing to re-run the smart pig, which immediately eliminates any gains which may otherwise have been made.

The types of pigs used for pre ILI cleaning depends on a variety of factors including the type and size of line, product running through the line, the existing maintenance pigging program. An experience pigging expert, like our team at Inline Services, can design a pre ILI cleaning program to meet your specific needs.

Our team will review your historical pigging information and provide guidance to ensure optimal performance of your intelligent pigging program such as recommending the best type of pipeline pig and most effective run frequency of each pig to ensure effective cleaning of the internal pipeline surface.

Contact Inline for Your Pre ILI Cleaning Needs

Inline Services specializes in helping customers determine the most effective pre ILI cleaning and ongoing pigging maintenance programs for any application. Click here to send us an email, or give us a call at (281) 401. 8142 | toll-free at (888) 973.007 to see how we can assist you with your next pipeline pigging maintenance program.