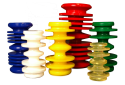

Inline Services manufactures VIPRS®/SUD Pigs for sanitary product recovery systems. Our sanitary pigging systems improve production efficiency by the recovery of product left in the pipe which reduces CIP costs and quantity of effluent sent to waste.

Wide Range of Features:

- Can be fully automated and PLC controlled

- For new installation or easily retrofitted

- Suitable for a range of aggressive temperature and chemical applications

- Will negotiate 90-degree elbows

Efficiency Maximized:

- Improved product yield by recovering virtually all product after batch transfer

- Reduces cleaning cycle time and efficiency

- Reduces waste emissions from cleaning operations

- Reduces piping – multiple products to use same line (batching sketch)

Complete Automation:

Sensors detect the presence of the pigs in the process system and communicate their position with a PLC. The pigs become part of the production and CIP process and are launched and retrieved automatically. Where cleanliness is paramount, the pigs are thoroughly washed in patented cleaning chambers, to 3A standards.

Applications Include:

- Foods

- Dairy

- Confectionery

- Beverage

- Pharmaceutical

- Fine Chemicals

- Beauty Products

- Cheese

- Milk

- Baby Food

- Syrup

- Juices

- Hand Creams

- Sauces

- Yogurt

VIPRS sanitary product recovery systems pigs can be manufactured from food grade materials and have been tested in Europe and U.S for their suitability.

Learn more by visiting our product recovery systems resources or get started by filling out a request for quote.